Silicon Carbide

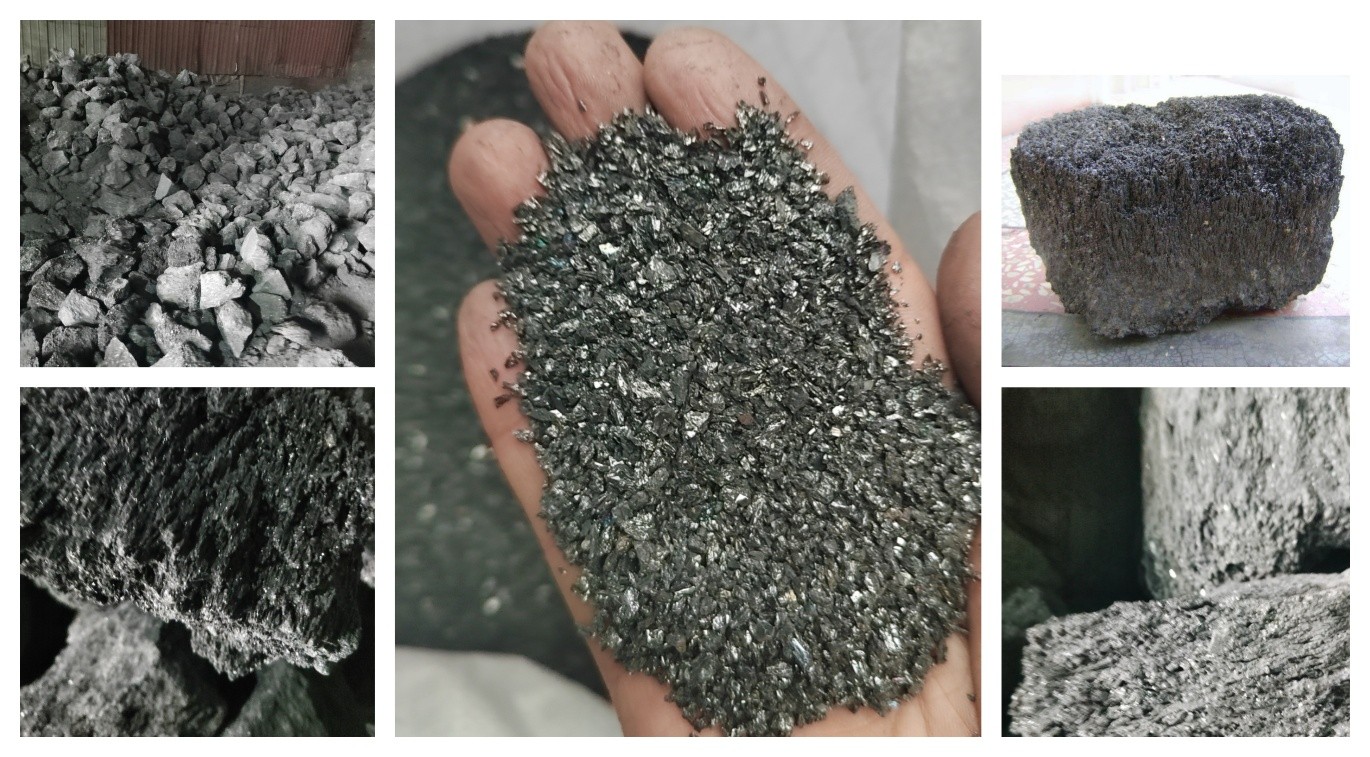

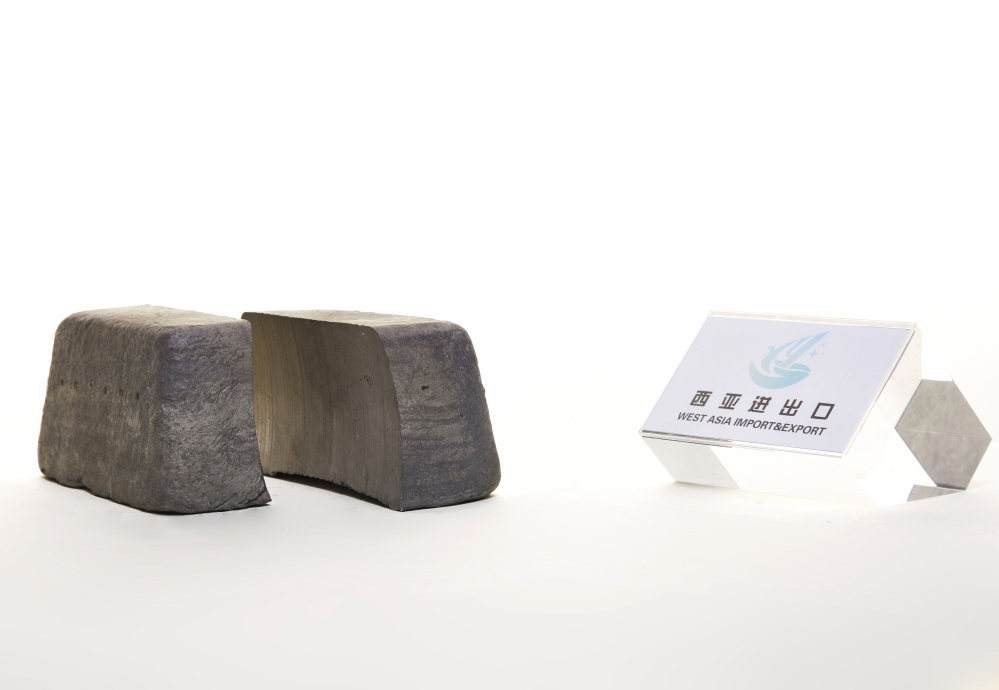

Silicon carbide can also be called SiC. According to the shape, there are silicon carbide blocks and silicon carbide powder.

- Grade: SiC #60 #70 #80 #90 #98.5

- Size: 1-10mm,10-100mm or customized

Product description

Silicon carbide is a non-metallic mineral product made at 1800℃ and above with quartz sand and anthracite or petroleum coke as basic raw materials. It can increase the carbon, silicon, and manganese absorption rates, and has completely replaced previously-used silicon iron and high-carbon manganese. It not only reduces costs but also improves the overall economic benefits of steelmaking. It is an important raw material widely used in refractory materials, steel industry, foundry industry

Brand | Component % | |||

SIC | F.C | Fe2O3 | ||

60# | 60min | 15-20 | 8-12 | 3.5max |

65# | 65min | 15-20 | 8-12 | 3.5max |

70# | 70min | 12-15 | 8-12 | 3.5max |

75# | 75min | 12-15 | 8-12 | 3.5max |

80# | 80min | 5-15 | 3.5max | |

85# | 85min | 5-15 | 3.5max | |

90# | 90min | 2-10 | 1.2max | |

95# | 95min | 0.6max | 1.2max | |

97# | 97min | 0.3max | 1.2max | |

98# | 98min | 0.3max | 0.8max | |

98.5# | 98.5min | 0.2max | 0.6max | |

Applications for black silicon carbide

1、Abrasives

It is mainly used for the grinding and polishing of grinding wheels, sandpaper, abrasive belts, whetstones, grinding blocks, grinding heads, grinding pastes, monocrystalline silicon, polycrystalline silicon in photovoltaic products, and piezoelectric crystals in the electronics industry.

2、steel

Taking advantage of silicon carbide's corrosion resistance, thermal shock resistance, wear resistance, and good heat conduction, it is used in the lining of large blast furnaces to improve the service life.

3、Metallurgical beneficiation

The hardness of silicon carbide is second only to diamond, and it has strong wear resistance. It is an ideal material for wear-resistant pipes, impellers, pump chambers, cyclones, and mine bucket linings. Its wear resistance is 5-20 times of cast iron and rubber service life, it is also one of the ideal materials for aviation runways.